GPX-C

GPX-C High Accuracy Screen Printers

Features

High accuracy printing for large panels

Consistent highly rigid machine design from the base to printing section enables high accuracy printing even for large panels, and durability which can maintain printing quality.

Reduces total costs

Solder supply and cleaning can be automated and the machine was designed considering work efficiency, which reduces the load on operators and minimizes the work time for changeover and maintenance.

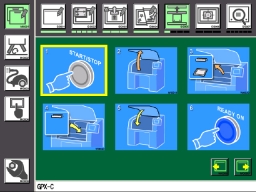

Icons and a layout based on procedures are used which provides intuitive operation that operators can easily understand and reduces the training time.

Reliable and efficient changeover

Setting mistakes and printing defects are prevented with the verification function for solder, squeegees, and masks. The cup type auto solder supply (option) enables using a general solder cup and this allows changeover to be performed in a short time without mistakes.

Specifications

| Item | GPX-C |

| PCB size(L x W) | 48 x 48 mm - 610 x 610 mm |

| Printing speed | 1 - 200 mm / second |

| Screen frame compensation accuracy | +/-0.012 mm @6σ (Cpk≥2) * Under conditions at Fuji. |

| Printing accuracy | +/-0.020 mm @6σ (Cpk≥2) * Under conditions at Fuji.(Using CeTaQ's measurement system) |

| PCB load time | 7.5 sec *PCB loading / unloading, mark reading and screen correction are included. |

| Squeegee pressure control | Print feedback control: Print setting range 10 - 250 N |

| Screen frame (L x W) | 750mm×750mm, 750mm×864mm, 29inch×29inch, Width can be adjusted by the millimeter from 550 to 750 |

| Squeegee type | Double squeegee |

| Machine dimensions | L: 1220 mm, W: 1650 mm, H: 1475 mm |

| Options |

|---|

| Paste doctor, Vacuum backup pin, Automatic solder supply unit, Local verification, Top clamp, Panel vacuum |

*Contact Fuji or sales agents for specific operating conditions and detailed specifications.